Products and Services

-

MR360

-

MR240

-

SMD mounting

-

Laser Cutting

-

Servo motor

-

Siplace

-

Nordic Radio Modul

-

SMT Stencil

MR360 Relay

The MR 360 R can detect the signal of any professional laser within 200 m. Its large - 25 cm long - sensor field captures the signal of leveling instruments in 360°.

It can be easily mounted with 2 wing nut clamps in the most visible place for the machine operator.

The MR 360 R machine control detector offers the following advantages:

- setting two types of accuracy levels;

- 40 hour operating time;

- large, bright directional arrows show the deviation from the level;

- the tilt control function shows the deviation from the vertical (e.g. excavator when placed on a spoon handle);

- memory function shows the last laser level.

Optional accessory: MR 360 wireless cabin display (pictured). Vacuum mounting option on the glass of the driver's cab.

Its transparent display does not disturb the machine operator.

Radio wave connection between the transmitter (MR 360 R) and the display.

MR240 Relay

It provides accurate information for all machine controls. Everything provides 240-degree perception rotational when using all rotating lasers.

Quick and effective help for the cutting edge of the dozer or grader or the bucket handle of the excavator for any rotating laser signal.

The 150 mm high sensor can catch the laser signal in 240°, which is the last level keeps it in its memory, so you can resume work at any time after a break.

The MR 240 machine control detector offers the following advantages:

- Extra strong magnetic attachment to the machine;

- setting two types of accuracy levels;

- large, bright LEDs show deviations from the indicated level;

SMT – SMD and THT installation

THT installation

SMT – SMD installation

In the case of through-hole technology (THT – Through Hole Technology), the terminals of the components (which can be rigid or flexible) into the holes on the component side of the printed circuit board to be installed and then on the other side of the panel (the soldering side) the terminals of the components we solder it down. This soldering is done using a wave soldering iron. The hole installation the disadvantage of this technology is that both sides of the assembly panel are used by the component.

Advantages of surface mounting technology:

-

No need to drill holes on the printed circuit board

-

Production processes are cheaper and can be better automated

-

The components take up less space, making them more practical

Versions of the surface mounting technology:

-

Clean surface mounting - we only mount using SMD components

– One-sided surface mounting (REFLOW)

– Double-sided surface mounting (Double REFLOW) -

Mixed installation - we install both SMD and traditional (through-hole) components

– SMD on one side, components with wire leads (RAD-CP) on the other

– For mixed surface-mounted side (REFLOW-RAD-CP)

We undertake SMD implantation both by hand and by machine in leaded and lead-free

designs

both.

If required, passive SMD components from our selection from our own warehouse, or possibly in advance

on the basis of discussion, we can provide it through individual procurement if a suitable number of

pieces is ordered.

For smd mounting of the printed circuit board on the position-numbered planting drawing and position number In addition to the material list, the computer PCB design system is required for programming the automatic machine gerber file generated by , and the file containing the data of the anti-solder mask on the SMD side.

If the panel is manufactured in an assembled version, we ask for this stock. (the PCB from the manufacturer) We design and manufacture the paste mask based on these files.

We look forward to your further questions about the service on these contacts!

Individual production, laser engraving, laser cutting

As a manufacturer, we undertake wood, plywood, paper, cardboard, leather, textiles, rubber, other plastics and unique production of designed plexiglass objects and products, even in large series, but single-piece orders we also fulfill.

Laser cutting makes it possible to create even the most complex shapes. The accuracy of the cut and its speed ensures fast, accurate execution of large-volume series productions.

The useful surface of the laser cutting-laser engraving machine we use1600x1000mm (63.0 "x 39.4") and its power is 100w. THE we give an offer for laser cutting based on the work. We look forward to your questions regarding the service on these contacts!

Siplace SMT PICK AND PLACE

![]()

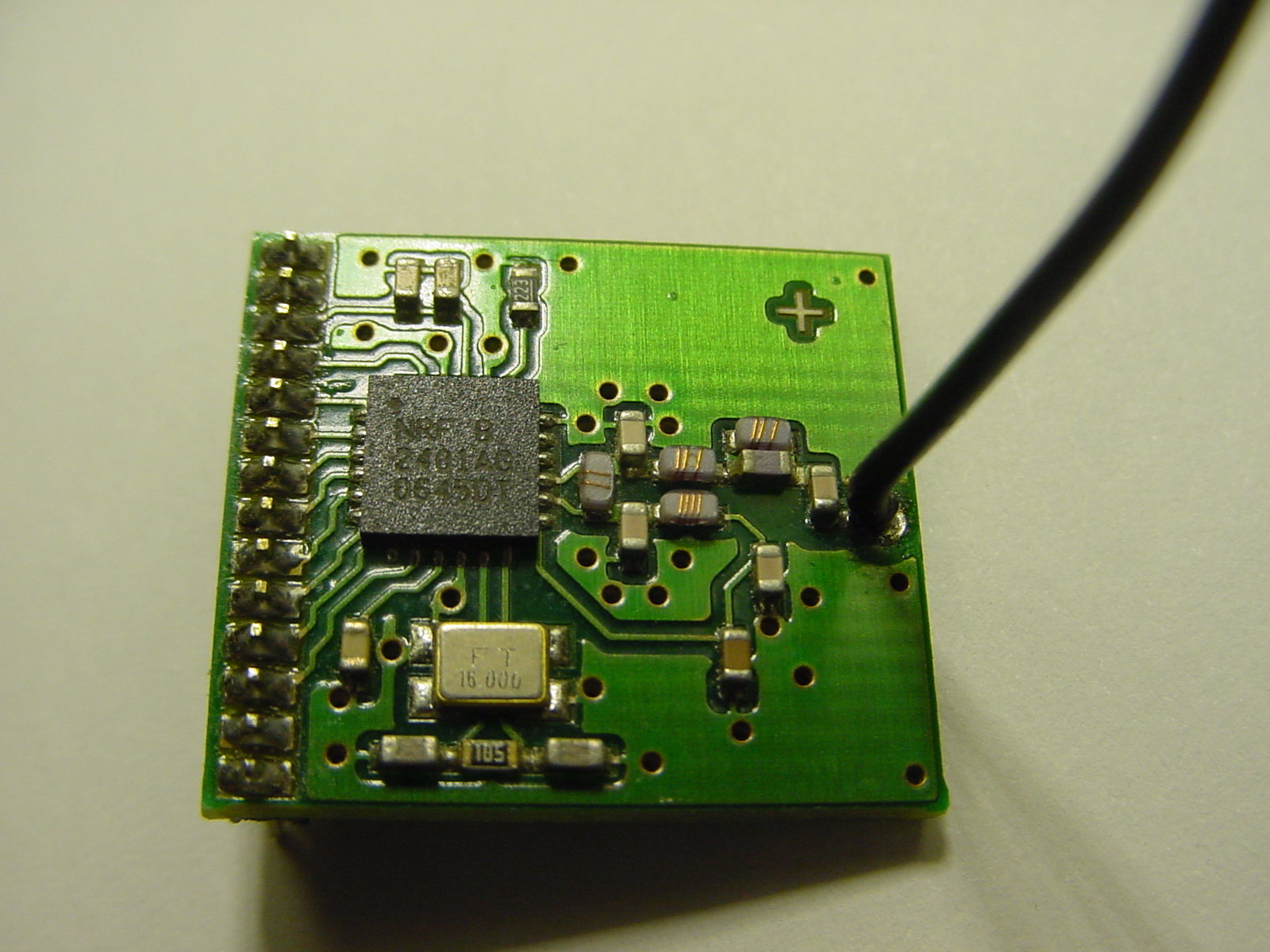

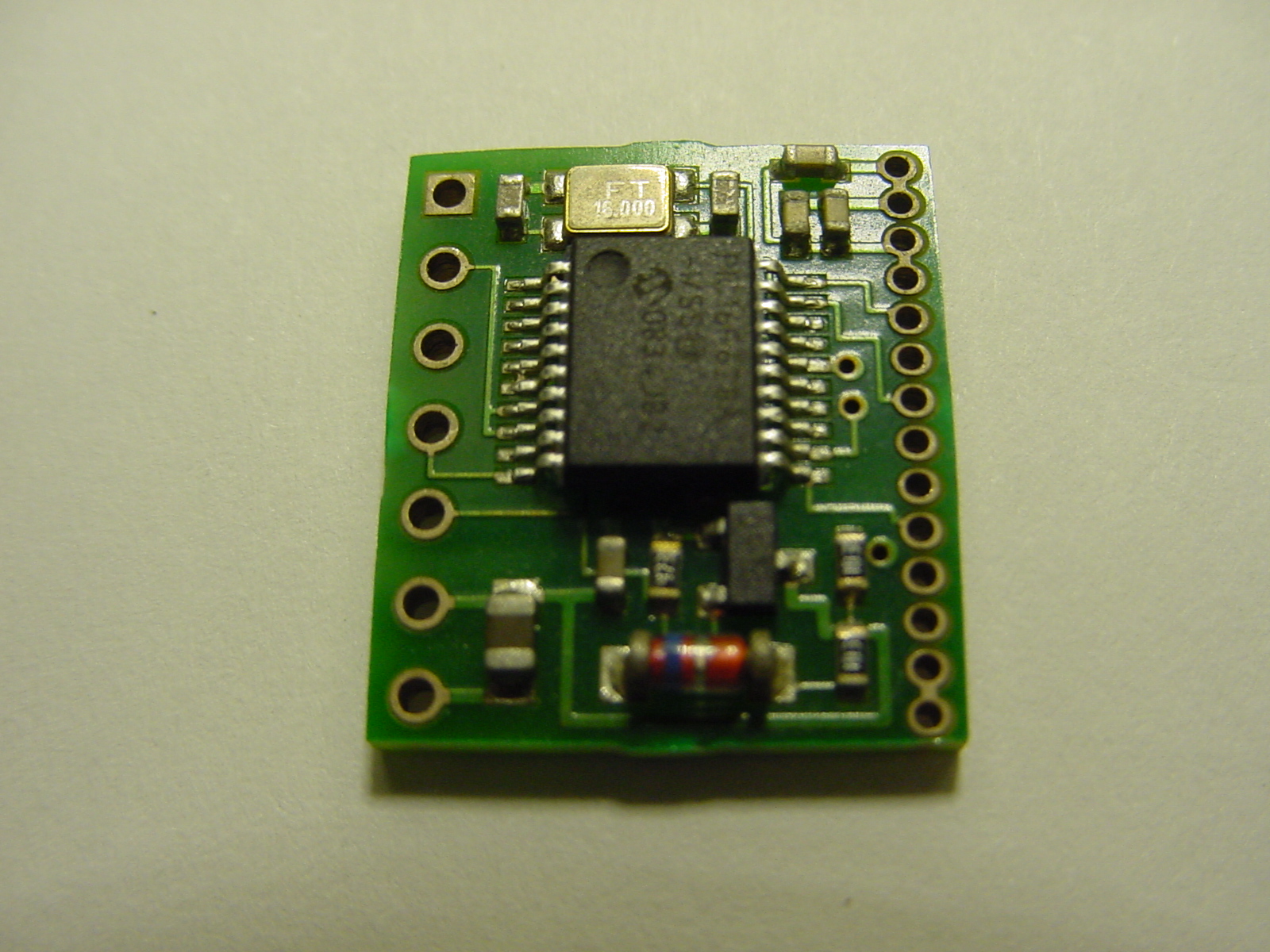

Nordic 2.4 GHz Radio module and control package

Nordic NRF2401

NRF2401 certified radio frequency (RF) transceiver modules for 2.4 GHz, license-free works in the usable, short-range ISM band of the IEEE 802.15.4TM specification The NRF2401 transceiver modules can be surface-mounted, and the 8, 16 or 32-bit PIC can work with hundreds of microcontrollers. For many applications requiring wireless networks ideal choice.

Properties:

- Output channel selection and protocol settings can be performed with extremely low consumption on the SPI interface

- Low operating voltage: 1.9-3.6V

- 125 channels, multipoint communication and frequency hopping

- Low consumption

- Internal FIFO compatible with different microprocessorsAlkalmazások

• Wireless PC peripherals

• Mouse, keyboard

• VoIP headset

• RF remote control

• Home and commercial automation

• Active RFID

• Games

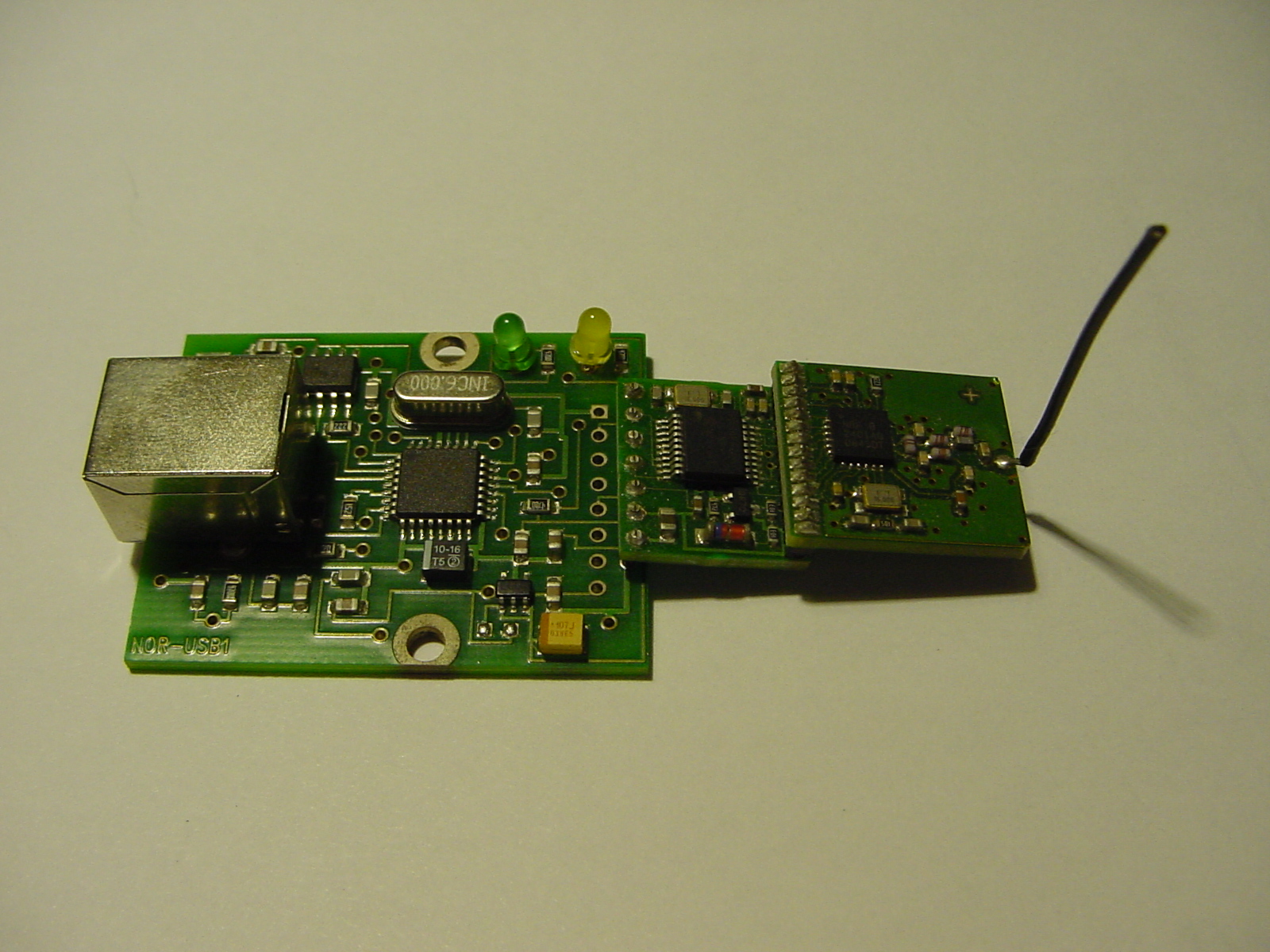

The microcontroller that controls the Nordic radio

The microcontroller controlling the radio is a PIC16F628A type IC. Between the radio module and the PC program handles data traffic. The values set in the program (RX, TX, Number of channels, speed etc.) the radio cannot remember, so it is advisable to use the microcontroller controller.

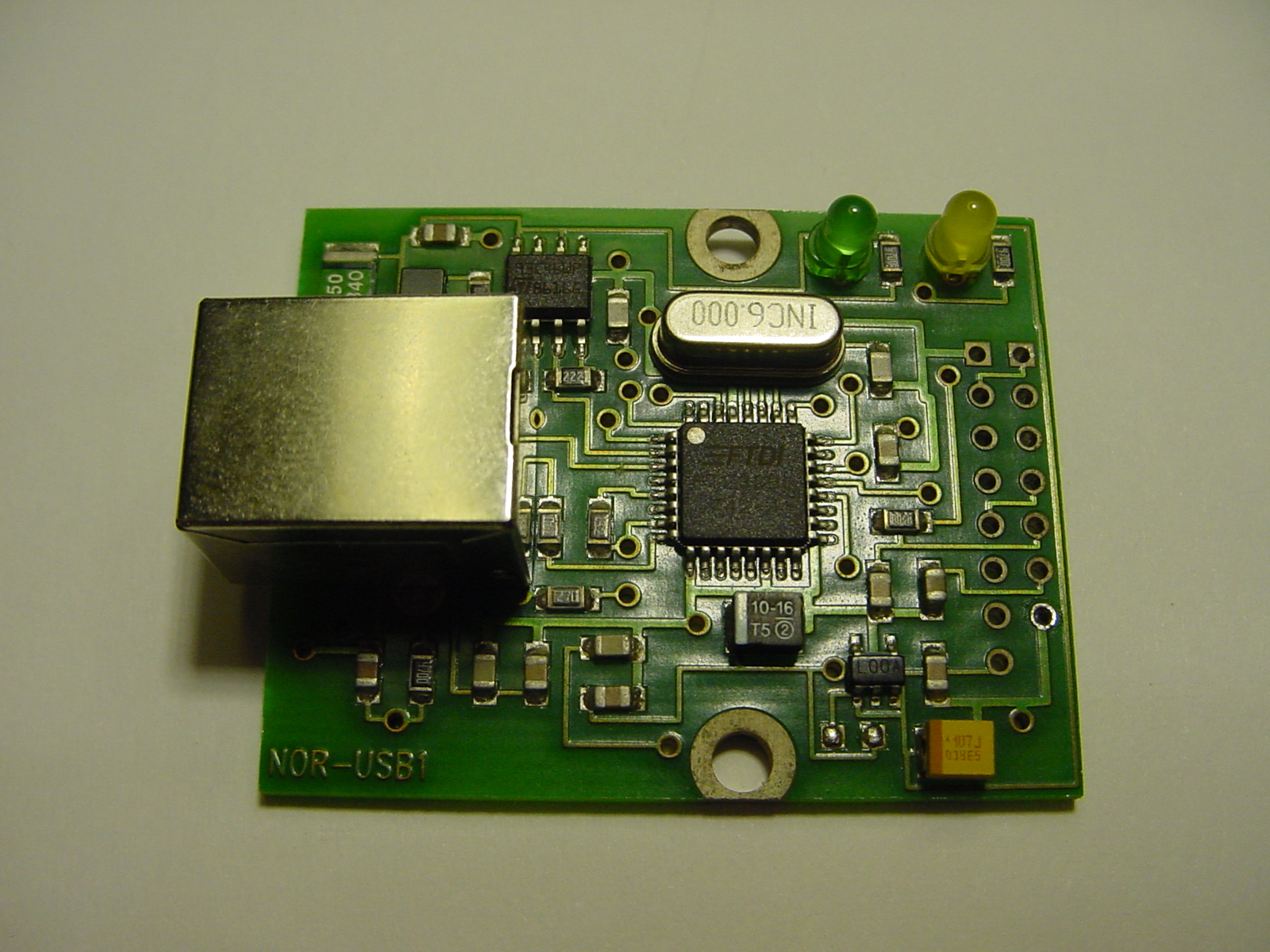

The communication module

Communication between the PC and the processor takes place via this module using USB. THE LEDs indicate data traffic to the user. The module is not only capable of Nordic radio to communicate but with almost anything, since communication takes place on a serial line, therefore all we made the data line available for this.

The modules are assembled

We look forward to your product-related questions on these contacts!

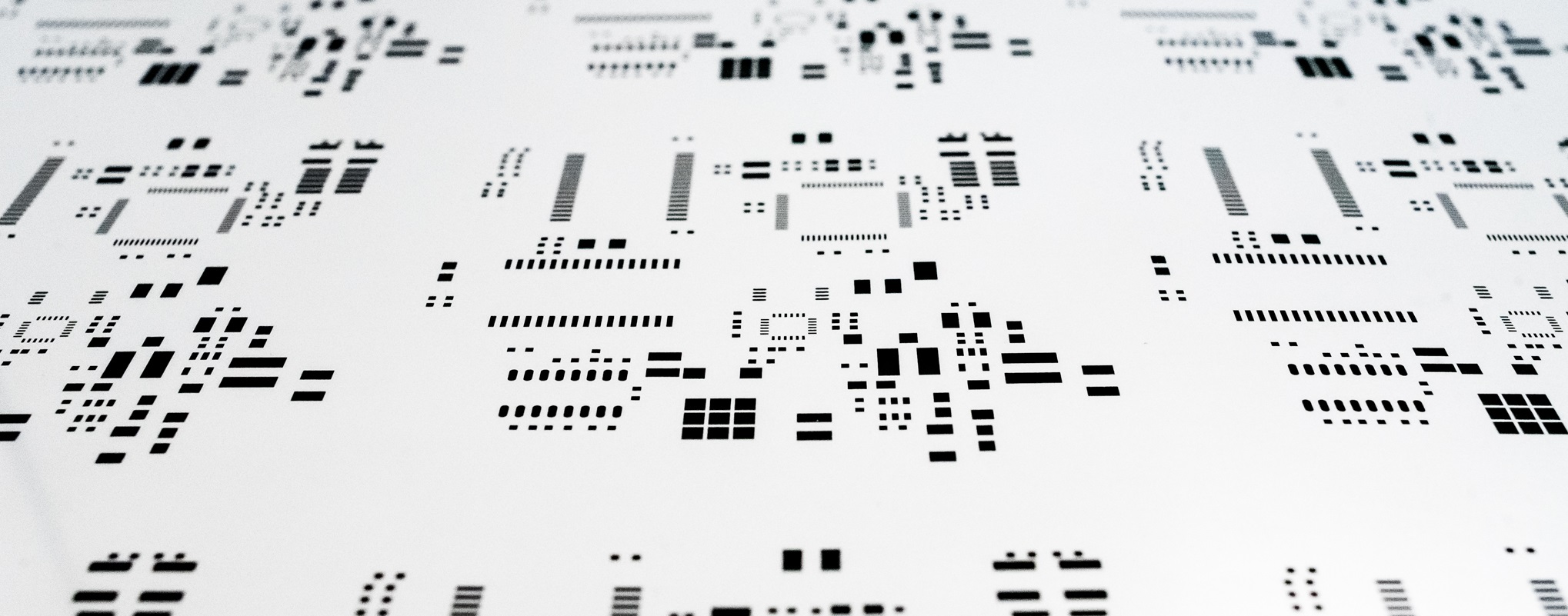

SMT Stencil

We do the work with LPKF laser stencil cutting CNC equipment, which is excellent quality laser cut enables the production of paste masks. Complex Electronics is a leading company with cutting-edge stencil technology. It's our company Surface Mount is one of the industry leaders in supplying quality laser cut templates Technology (SMT) industry. Proudly offering exceptional quality, delivery and service we have earned the respect of many of our customers Accurate and fast laser cutting of stainless steel stencils Competitive price with excellent quality Even with same-day delivery Electropolishing Nano Coating LPKF ZelFlex stencil DEK Stencil Custom size frameless stencil Stretched stencil with aluminum frame Production of micro mechanical parts